everything but the kitchen sink...oh, and that too!

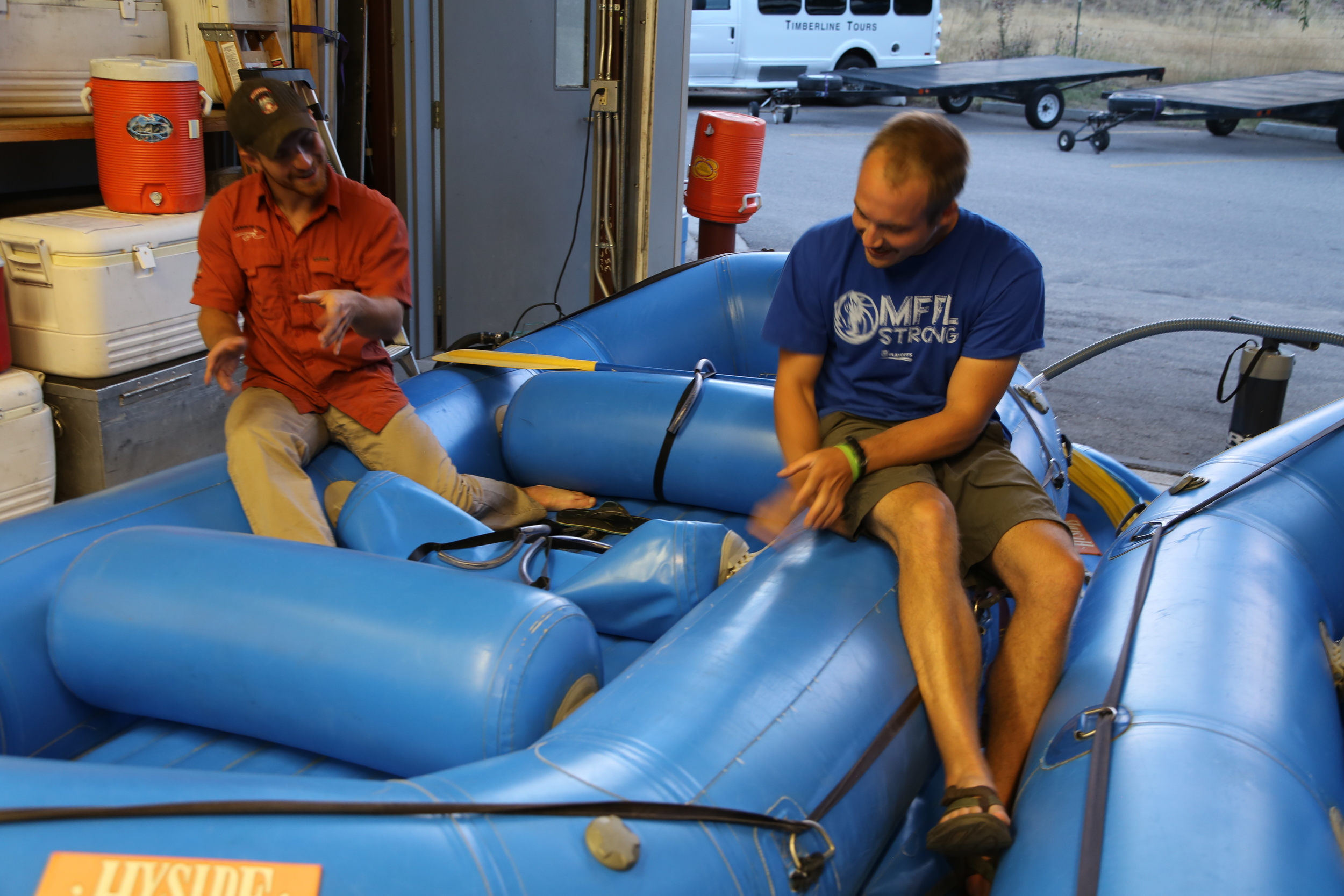

/Two nights before the big Gore Canyon Race (a race down a Class IV-V stretch of whitewater on the upper Colorado River), Christian was planning his lines with his R2 buddy Shawn (you'll also recall he was the one that convinced us to rip up the subflooring) and then to distract from his fear, helping me install the new Rocket Pump we'd bought for our almost finished kitchen.

Shawn and Christian getting to know their race boat and talking about their lines.

Christian wanted to make sure that I mentioned that he and Shawn won gold in the R2 division. They're unsure of their time, but they were definitely first (...because they were the only boat in their division to finish).

This is Shawn and Christian about to huck a 12-foot waterfall rapid called Tunnel Falls. (I was lucky enough to get taken into a the canyon by a railroad truck to photograph this spot for the race.)

Kitchen counter in the foreground, Campbulance in the background.

A very big drill bit.

Making the hole for the Rocket Pump.

Prior to ordering the Rocket Pump, Christian had done some Googling to see what kind of instructions, etc he could find on the subject. There were none. Turns out, it's because you don't need any. The pump is literally installed with two screws (included) and you simply jam the water hose up onto the bottom and boom, installation complete.

Installing a Rocket Pump = drilling a hole and screwing in the two screws it comes with.

Getting ready to test the pump for the first time.

I think I was a teeny bit annoyed that the one photo taken of me during this project was of me vacuuming up the aftermath. I promise I did more than just take photos! (I think...it's been a few months...I could be wrong.)