12.26.15 Curtains, bookshelf and layout changes.

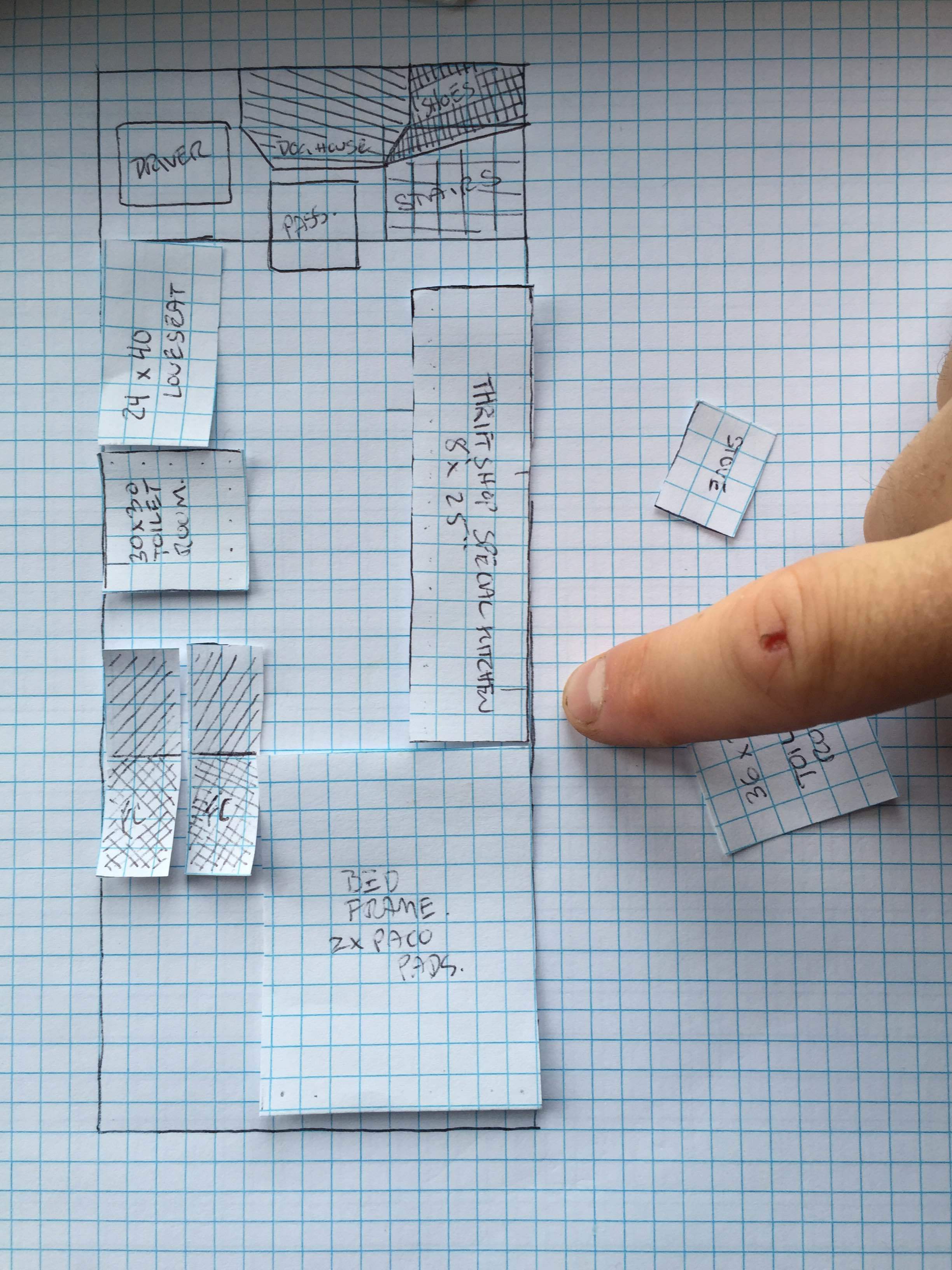

/Christian and I had been a little divided on what to do regarding our planned toilet room. If you remember in the original layout plans (I'll post the photo below), we had intended to do the toilet room in the center beside the living room seat/couch. However, once we lived in the bus for a while, we began to doubt whether splitting up the space that much would work for us, so we went over our other options.

In the end, we decided to move our filing cabinets and switch their spot with the toilet room after realizing the space they were taking up was the perfect size and location for our future toilet.

We took turns sitting in the space to make sure it was a comfortable size.

One of the other top projects we needed to get done for both function and necessity was curtains. Christian had pulled the insulation off of the windows that we were using as our temporary coverings, so the need became urgent and I was sent to Hobby Lobby to procure supplies.

Christian added two layers of foam insulation to the walls before putting OSB over it for some extra insulation. Now that we had a working heater, we realized how much some simple walls and insulation would help our cause.

Here's a photo of the filing cabinets moved and the toilet room walls beginning to take shape.

I spent a lot of time (and money, to be honest) at Hobby Lobby after hemming and hawing about what fabrics I wanted to us. We wanted thick insulating curtains, so in addition to choosing a nice patterned duck and the heaviest duty blackout fabric in the store, I also got some thick Thermolam to sew between the layers as insulation.

We had sold through our back stock of trees and weren't getting any more shipments, so we took advantage of the shade of the tent to set up our work space. Christian was working on the walls and then a book shelf while I began to tackle the large sewing project before me.

I did a lot of reading before I ever sewed my first seam.

As a sewing technique, I went with a suggestion from my mom, which was to sew everything inside out like a pillow case and then turn it right side out to do the finished seam on the top. I ended up only doing the two sides like this and then sewing a folded over seam on the top and bottom.

It took me all day to conquer just one curtain, but I was proudly making progress while Christian continued work on his bookshelf.

I'm extremely proud of Christian's ingenuity with his bookshelf. He had this idea to build a small shelf beneath the foot of the bed to utilize the space there. Because of wanting to be able to access the garage space when moving the motorbikes in and out, he didn't want it to be permanent. Instead, he built it on wheels and even added a spot for Loulou's litterbox that will be hidden once he puts a face on the shelf.

He also built walls for the toilet room and installed them (sorry, no photos of that…I was too busy wrestling with my sewing machine and way too much fabric).

In addition to moving the filing cabinets out, we also shuffled around the hanging space to accommodate some planned changes to the garage space (more on that later). With the filing cabinets out, it still divides the space, but not nearly as much as a walled room would have, so we're pretty happy with our decision. Honestly, we almost nixed the idea of the toilet room at all, but part of our upgrade to the bus was specifically to include a toilet, so we figured we should make it happen.

After finishing one curtain, I was both exhausted and energized. Most of the curtains would cover two windows, so it was a large amount of very thick heavy duty fabric to be working with for someone as inexperienced as I am. I kept running into issues with the machine along the way, so each curtain seemed to take longer and longer. The curtains for the living space are completely done now (I'll have to get a good photo of them later) and I'm still working on the ones for the front windows and the cab space (the odd shapes and sizes are giving me a run for my money).

They make a world of difference for light and insulation, so we're happy I went with such heavy duty materials.