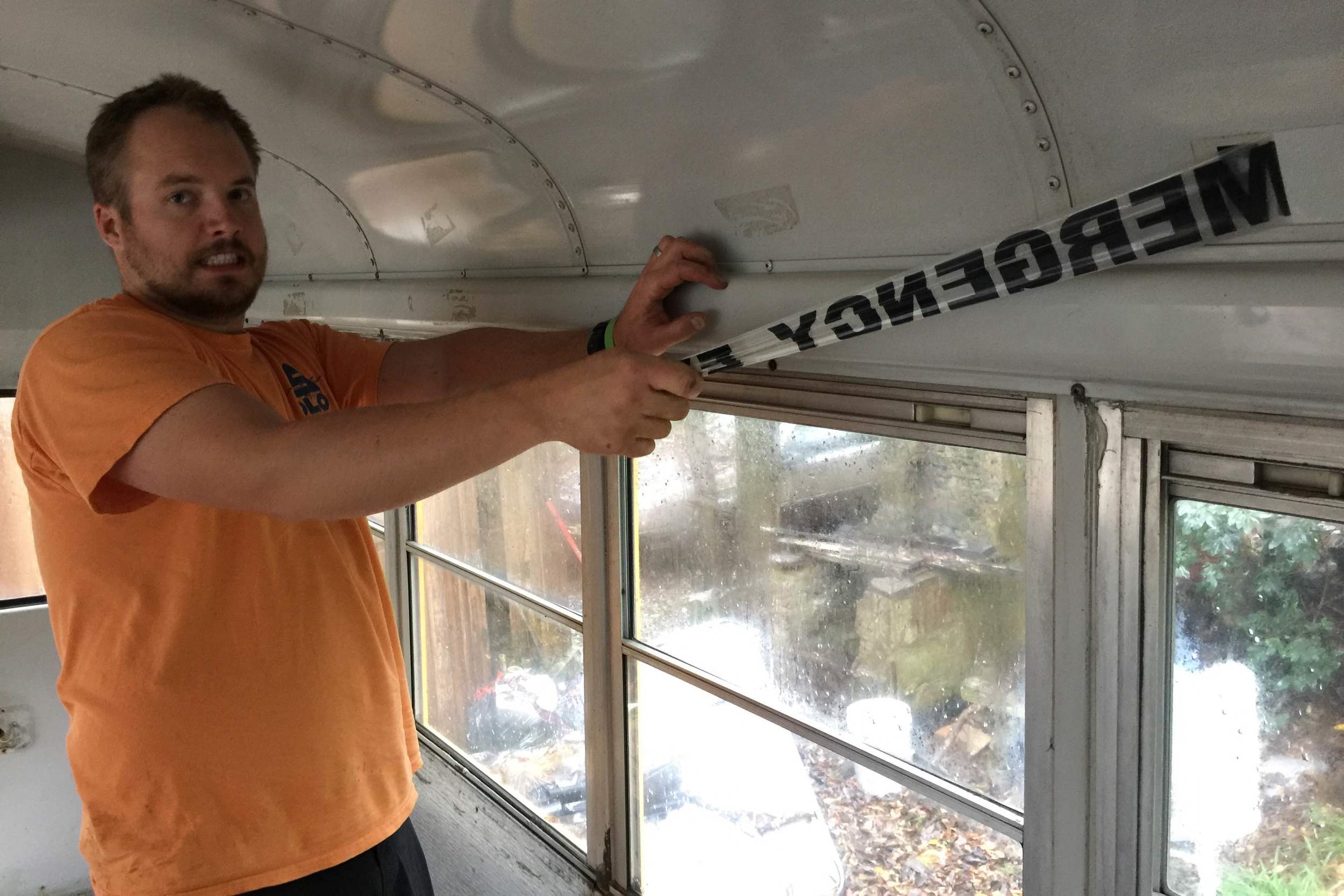

11.02.15 - Pickin and Pullin - Day 6.

/While Stubbs sat in the shop at Ace Muffler and Welding in Searcy for some floor repair, we ventured out for some shopping for the conversion project. We NEED another seat, a passenger/copilot/navigator seat for the bus, and we'd really like it to spin and be usable as a dining room seat, so we visited not one but three Pick-N-Pull junkyards today to look for a rotating captains chair. New ones go for upwards of $600, but we're hoping to get done with this part of the project for under a $100.

For those of you not familiar with a Pick-N-Pull, or any other choose-your-own-adventure junkyard, let me explain how they work. You show up with your own tools (and a whole-new-world grin) and scour rows upon rows of totaled vehicles looking for the part you want. Anything from door handles to engine blocks are available, and you're responsible for pulling the part from the vehicle. Then you drag the part up to the checkout window, pay the nice folks who own the junkyard, and haul the goods away.

We found two rotating plates that once attached captains' chairs to the body of an early '90's Chevy Astro EXT. Hopefully, some light fabrication and welding will help us create a passenger's seat that will rotate 180 degrees to function as a dining room seat for when Stubbs is parked. We'll see.

We haven't found a seat to attach to the rotating plate yet, but there was one that interested us at the 1st junkyard we visited, and we may return for it soon. This is not it, but rather its runner-up. No merlot velour for us today.

In between the junkyards we visited two Habitat for Humanity Restore... stores. If you've never been, go. They are totally helpful and fun, and offer all sorts of home goods at super low prices, like a Goodwill/thrift-shop for remodel supplies.

Chelsea nearly had to be dragged away from this wingback chair. She was convinced we could make it work as a copilot's chair. (I think she just really liked how nap friendly it was.)

We also had some ideas about using abandoned filing cabinets as storage. Maybe some fancy painter's tape work and some spray paint will give us the look we want? Stay tuned!